Quality

Quality Control System

Design Phase

CAD design optimization to ensure structural strength and functionality.

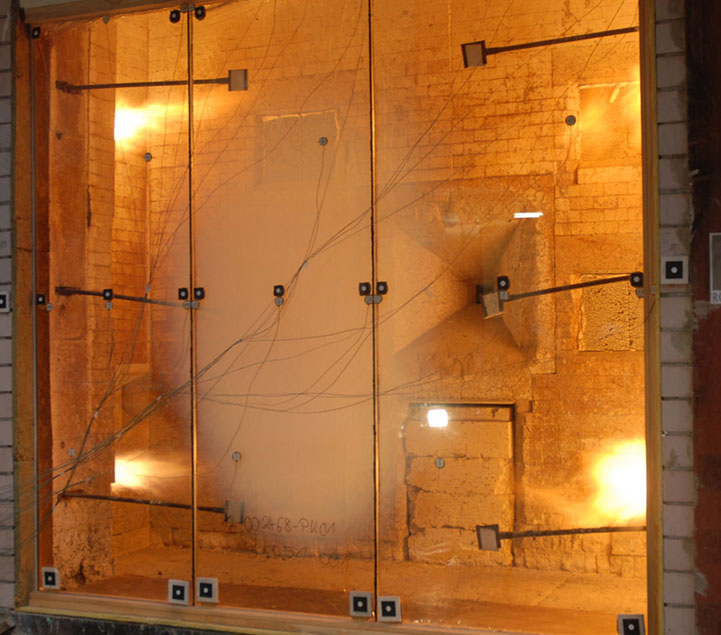

3D simulation testing to verify product performance (e.g. fireproof, soundproof, radiation protection).

Production Stage

Modernized assembly line to ensure consistency.

Real-time monitoring of key parameters (e.g. dimensional accuracy, material density).

Inspection Stage

Strict quality testing process (including radiation protection test, antibacterial performance test).

Third party laboratory certification (SGS, TÜV).

Detection

Testing Capabilities

Space Creation

Innovative Design for Smarter Medical Spaces

At Kaiyue Doors, we combine advanced technology with human-centered design to create medical doors that redefine safety and functionality. Our R&D team utilizes CAD-driven design and 3D simulation testing to ensure that every door, from radiation-proof barriers to antimicrobial surfaces, meets high-performance standards. Our doors focus on modularity and aesthetic integration, offering not only robust functionality but also enhancing the overall medical environment.

Manufacture

Precision Manufacturing

Our advanced production facilities are equipped with automated assembly lines and real-time quality monitoring systems. We maintain strict control over every step of the production process. Through ISO-certified workflows and a commitment to eco-friendly materials, the doors we provide are not only reliable but also sustainable.